The following is a transcription of an interview with V.J. Nathan of QUA.

The following is a transcription of an interview with V.J. Nathan of QUA.

What can Ultrafiltration membranes do?

Ultrafiltration is a membrane filtration process which can remove all the particulates and high molecular weight solutes form water / solvent depending on the pore size of the membrane. The normal pore size is in the range of 0.01 to 0.03 micron. This relates to about 100,000 to 500,000 MWCO (molecular weight cut of).

Ultrafiltration operates in the molecular range of filtration and is used for removal of bacteria, microorganisms, colloidal matter, proteins, pyrogens and other macro molecules larger than the membrane pore size.

In municipal and industrial treatment, ultrafiltration can replace media filter or act as a polisher after the media filter to improve substantially and the quality of the treated water.

Ultrafiltration generally does not require any chemicals like coagulation or flocculation and thus also any pH adjustments. The membrane can function under a wide pH range.

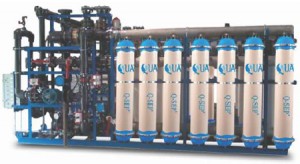

In our manufacturing facility, QUA Group manufactures pressurized hollow fiber membranes with surface area up to 60 m2 (645ft2).

What is hollow fiber ultrafiltration?

Ultrafiltration membranes are available in 3 configurations. These are hollow fiber, tubular and flat sheet. Hollow fiber is the most popular of these configurations widely used in municipal and industrial filtration replacing the multimedia filter. The fibers are normally in 0.3 to 2 mm internal diameter and are bundled together with potting mostly at both the ends. The hollow fiber bundle overall diameter and length depends on the surface area requirement which is basically limited by stability & structure of the fiber bundle and varies from manufacturer to manufacturer.

Again Hollow fiber membranes are available in 2 configurations namely pressurized inside to out or outside to in as well outside to in submerged type. Each of these types has their own advantages and disadvantages.

The most popular hollow fiber configuration is the pressurized type due to its economy and ease of operation and can be utilized in all flow ranges.

Flat membranes are submerged type and mostly used in MBR waste water recycle application.

Tubular membranes are very expensive due to low surface area but quite largely used in high turbid / suspended solid water / waste water where the flow is not very large.

How is Q-SEP different from other types of membranes?

Q-SEP membrane is protected by an exclusive patent in the fiber preparation process termed cloud point precipitation process. This ensures uniform pore distribution as well high porosity thought out the entire surface area of the fiber. This ensures a higher operating flux, lower TMP and superior treated water quality.

Q-SEP hollow fiber membranes are specially modified hydrophilic PES membrane which during operation maintains a layer of water next to the membrane surface and reduces fouling. Reduced fouling means reduced CEB and CIP requirement.

Q-SEP hollow fiber UF membranes are NSF 61(Toxicity) certified for drinking water use as well NSF tested to latest EPA – LT2 requirement with a performance of > 6 log reduction of bacteria removal.

Hollow fiber membranes are very economical compared to tubular or flat sheet type as a large surface area can be packed in to a small volume.

Q-SEP pressurized hollow fiber membranes are also highly cost effective as it can be operated at much higher flux compared to submerged type. This means lesser membrane area requirement.

What industries use ultrafiltration membranes?

Surface Water Treatment

Municipal—Giardia / Cryptosporidium removal

Industrial—Pretreatment to RO

Seawater Desalination

Pretreatment to RO

Wastewater Treatment

Municipal—Waste water recycle

Industrial—Recycle application to produced process water ( example Textile effluent, Refinery / Petrochemical effluent, Cooling Tower Blow down, MMF Backwash water etc.