Project Description

QUA’s Rugged EnviQ® Submerged MBR Efficiently Addresses Effluent Treatment Challenge at a Leading Pharma Company

Background

Background

Client: Leading Pharma Company India

Feed Water Capacity: 15850.3 GPD (60 m3/day)

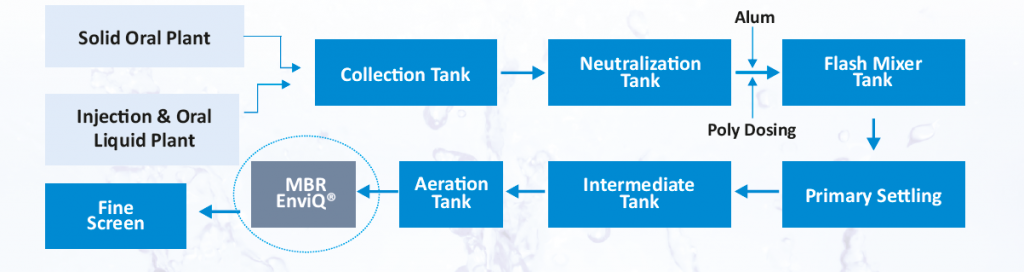

The State and Central Pollution Control Boards mandate the treatment of effluent to be conducted with a focus on recycling and reusing the treated water. QUA was approached by the client to tackle the challenge of effectively treating complex effluent using the existing conventional system. The project faced limitations due to limited available space and a restricted footprint.

QUA introduced the EnviQ®24CV model, an innovative submerged membrane bioreactor (MBR) flat sheet membrane solution. As part of their approach, the QUA team conducted a thorough audit of the existing facility, taking into account various input parameters such as effluent complexity, space availability, and issues related to the manual mode plant.

With the implementation of the EnviQ®24CV, the system now offers automated operations, ensuring consistently high product quality with turbidity levels below 1NT. The flat sheet PVDF membranes, known for their robustness and durability, provided an ideal and effective solution. QUA’s membrane design was specifically tailored to enhance the operational and maintenance convenience of the MBR facility. The result is a reliable and high-quality effluent achieved through consistent ultrafiltration processes.

Membrane system design offered:

| QUA MBR Model | Active Area (M2) | Nominal Pore Size (Microns) |

Permeate Flux (lmh) | Required MLSS (mg/l) | Air Flow Rate (nm3/hr) | Product Flow (M3/hr) |

|---|---|---|---|---|---|---|

| EnviQ 24CV | 240 m2 | 0.04 | 16 | 3,000-8,000 | 80 | 3 |

Results

Since March 2022, the system has been operating with great success, fully meeting all the client’s requirements. The water chemistry has remained consistently stable throughout this period, and the permeate flow has been consistently maintained within the range of 3 m3/hr.