Project Description

QUA’s Q-SEP® Ultrafiltration Membranes Effectively Treat Complex Effluent at Leading Integrated Steel Plant

Background

Background

Client: Leading Greenfield Integrated Steel Plant

Existing ETP capacity: 3,434,356 GPD (13,000 m3/day)

Challenges :

- Optimize wastewater treatment for reverse osmosis (RO) feed for the site’s zero liquid discharge (ZLD) plant.

- Adhere to established pollution control standards and guidelines for treating and releasing wastewater.

The original treatment system installed by a previous vendor underperformed and failed to function correctly within two months post-installation, prompting the client to decommission it. The client turned to QUA for its expertise and proven solutions.

After a comprehensive evaluation, the client selected Q-Sep 8012, a state-of-the-art low-pressure hollow fiber ultrafiltration system known for its superior performance. The decision to implement this advanced technology was made based on its robust secondary treatment capabilities, exceptional performance, ability to handle a Silt Density Index (SDI) of less than 3, and its proven effectiveness in water treatment applications.

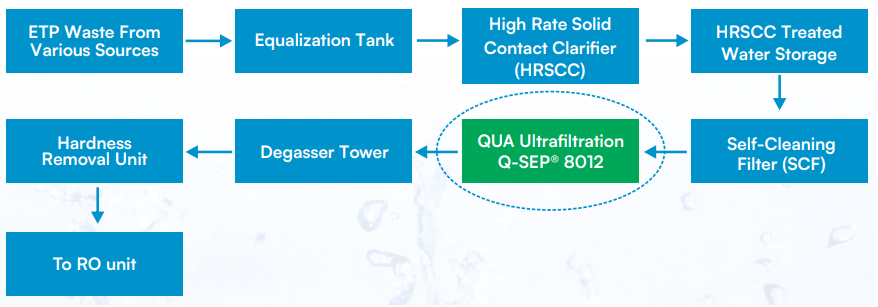

Plant Scheme :

Membrane system design offered :

|

QUA UF Model |

No. of Streams | No. of UF Modules Per Unit | Permeate Flow Per Stream | Design Feed Water Turbidity (NTU) | Product Water Turbidity (NTU) |

| Q-SEP® Outside-In | 02 | 96 | 267 x 2 m3/hr | 50 |

0.1 |

Results

Since its commissioning in April 2023, the ultrafiltration system has delivered uninterrupted, high-performance results. The system has consistently treated effluent treatment plant water, consistently achieving the clients stringent quality specifications. The clarity of the product water has consistently remained between 0.1 to 0.23 Nephelometric Turbidity Units (NTU), and the permeate flow has been consistently sustained at 267m3/hr in each stream without any reduction in overall output. The RO permeate is effectively utilized for the power plant application.