Project Description

QUA’s EnviQ® Submerged Membrane Bioreactor (MBR) Successfully Treats Wastewater at a Luxury Hotel in India

Background

Background

QUA was approached by a client who was encountering challenges in recycling water through their existing conventional treatment method. The client was unable to utilize the sewage treatment plant (STP) to discharge water for their specific needs, requiring high-quality water. Additionally, the existing facility had a very limited footprint, making the task of upgrading the system a significant challenge.

QUA Solution

QUA offered the EnviQ 440 XL model, a submerged membrane bioreactor (MBR) flat sheet membrane solution, which was evaluated against multiple criteria, including desired membrane surface area flux, footprint, capital investment, as well as low operation and maintenance costs. This innovative solution also reduces the need for secondary and tertiary clarifier treatment.

QUA offered the EnviQ 440 XL model, a submerged membrane bioreactor (MBR) flat sheet membrane solution, which was evaluated against multiple criteria, including desired membrane surface area flux, footprint, capital investment, as well as low operation and maintenance costs. This innovative solution also reduces the need for secondary and tertiary clarifier treatment.

QUA’s membranes are engineered to enhance the operational efficiency and maintenance of MBR facilities. They ensure reliable and consistent production of ultrafiltration quality effluent. EnviQ’s cutting-edge design incorporates a robust PVDF flat sheet membrane and a proprietary diffuser system, guaranteeing exceptional durability and performance.

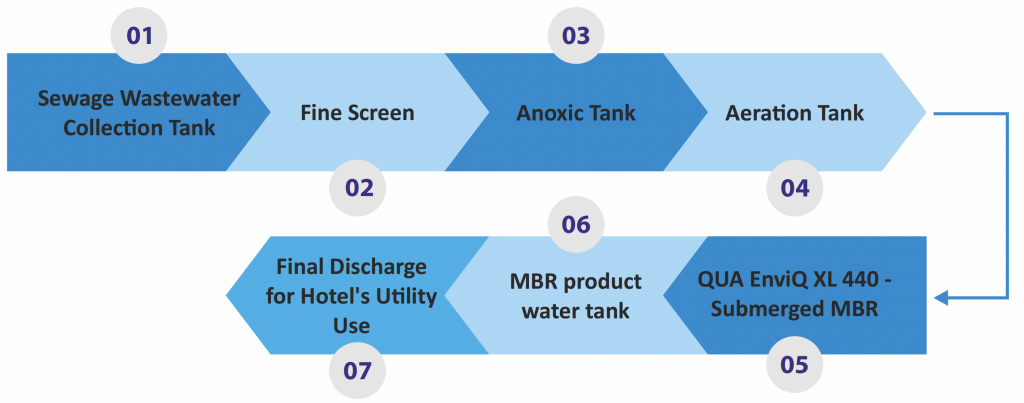

Plant scheme offered:

Membrane system design offered:

| QUA MBR Model | Active Area (M2) | Pore Size (Microns) | Permeate Flux (lmh) | Required MLSS (mg/l) | Air Flow Rate (nm3/hr) | Product Flow (M3/hr) |

|---|---|---|---|---|---|---|

| EnviQ 440 XL | 440 m2 | 0.04 | 22.7 LMH | 3,000-8,000 | 110 | 10-12 |

Results

The system has consistently operated, meeting the client’s requirements since its implementation in 2021. The water chemistry has remained constant, ensuring stability and reliability, and the permeate flow has been consistently maintained within the range of 10-12 m3/hr, demonstrating the MBR system’s steady performance over time.