Fractional Electrodeionization (FEDI) Process

The Electrodeionization (EDI) process, invented over 20 years ago, is a continuous, chemical-free method that removes ionized and ionizable impurities from the feed water. EDI is most commonly used to treat Reverse Osmosis (RO); permeate and replace Mixed Bed (MB) ion exchange; producing ultrapure water of up to 18 M Ω.cm. EDI eliminates the need to store and handle hazardous chemicals required for resin regeneration and the associated neutralization steps.

QUA’s Fractional Electrodeionization (FEDI) process is an advancement of EDI and was developed by taking into account the limitations of conventional EDI. FEDI has been in the market for over five years now and has been installed in power stations, refineries, and more. Many of these FEDI systems supplied are some of the largest installed systems in the world.

The patented dual voltage process allows for a higher flexibility and tolerance to inlet water conditions, thus lowering the risk of scaling, and improving the plant’s design economics and reliability. FEDI products are supported with CE conformity certificates.

FEDI Technology

Making a good technology even better

There are two types of ionic impurities removed in an EDI process; strongly ionized impurities (divalent ions such as Ca, Mg, SO4 and monovalent ions such as Na, Cl and HCO3) and weakly ionized impurities (such as CO2 B and SiO2). Both types of ionic impurities require a different driving force (current) for movement and separation. Strongly ionized impurities require less current, whereas weakly ionized impurities require more. Rather than applying one current to the entire module, the FEDI process differentiates the treatment of weakly ionized and strongly ionized impurities by applying different currents and voltages in a two stage process. This allows a significant portion of strongly ionized impurities, mainly the divalent ions, which can cause precipitation at a higher voltage, to be removed in Stage-1. Subsequently, a higher voltage is applied for removing weakly ionized impurities in Stage-2. The rejected ions from both stages are removed, using separate reject streams, thus preventing hardness precipitation.

FEDI Two Stage Separation

Hardness is the scaling component and the main limiting factor for feed conditions in a conventional EDI. By incorporating a two-stage separation process with different voltages the FEDI process is able to:

- Achieve a higher hardness tolerance by having distinctly different concentrate chambers with separate reject streams and thus reducing the potential of hardness scaling.

- Optimize power consumption by using higher electrical current only where required.

- Ensure the best water quality, continuously & consistently by removing a major part of the deionization load in the ‘hardness removal zone’, while residual ionic impurities are effectively removed in the ‘silica removal zone’, which stays in a polishing mode.

Advantages to FEDI:

MB |

EDI |

FEDI® |

|

| Capable of generating ultra-pure water without having to discharge chemical laden regeneration waste streams | X | ✓ | ✓ |

| Treated Water Quality Improvements

Produces from 1 MΩ.cm high purity water to 18 MΩ.cm ultra-pure water with very low levels of silica & boron |

✓ | ✓ | ✓ |

| Ease of operation | X | ✓ | ✓ |

| Flexibility to handle feed condition variations due to dual voltage operation | N/A | X | ✓ |

| Higher feed hardness tolerance, thus avoiding or eliminating module scaling | N/A | X | ✓ |

| Effective and efficient removal of weakly and strongly ionized impurities | N/A | X | ✓ |

| Optimum power consumption | N/A | X | ✓ |

FEDI-2

FEDI HF

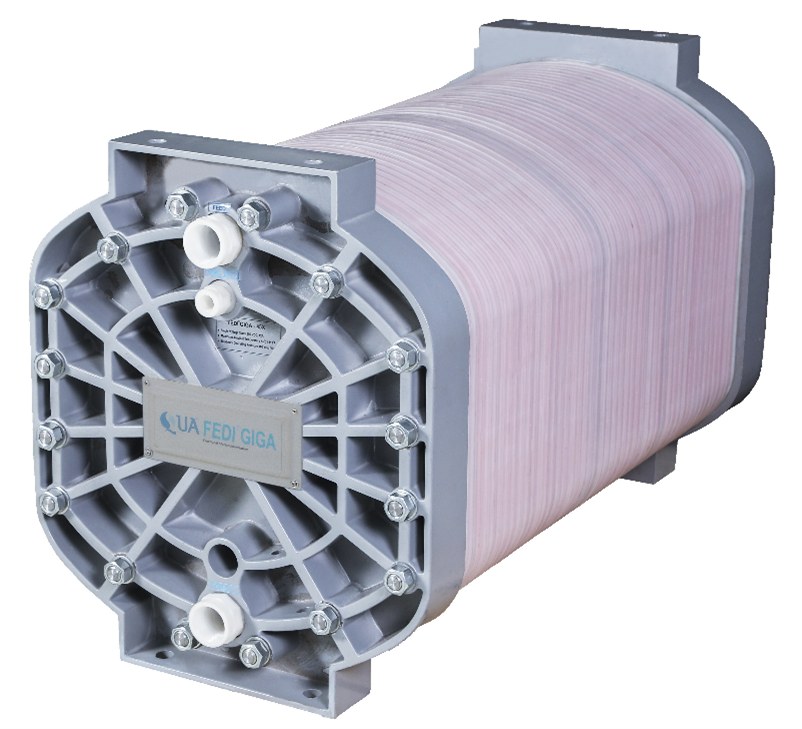

FEDI GIGA

FEDI RX

FEDI-2

FEDI® stacks are designed to produce high purity water up to 18 MΩ.cm using a patented process with double sets of electrodes per stack. The FEDI® stack is designed to replace mixed bed technology and produces pure water continuously, without the use of regeneration chemicals. Applications include the semiconductor, power, pharmaceutical, and food and beverage industries. FEDI-2 is available in two operating modes: Dual Voltage (DV) and Single Voltage (SV). The stacks contain media on the concentrate side, eliminating the need for a salt injection

Advantages to FEDI-2:

| High hardness tolerance stack | Reduces cleaning frequency, while increasing stack reliability |

| Reduces system cost | Placed after single Pass RO system |

| Low feed pressure | No counter current operation required |

| High recovery | Reduced concentrate flow |

| Wide range of flows | FEDI-2 stacks comes with different variants to cater to wide range of flow from as low as 0.25 m3/hr (1.1 gpm) to as high as 7.5 m3/hr (33 gpm) |

| CE Certified | FEDI-2 stacks comply with 2014/35/EU directive on electrical safety |

| Ultra-pure water quality | Produces ultra-pure quality water of up to 18 MΩ.cm.

Meets water specifications for high pressure boilers and gas turbines, as well as a variety of other application |

FEDI HF

FEDI stacks are designed to produce ultrapure water up to 18 MΩ.cm using a patented process with double sets of electrodes per stack. FEDI replaces mixed bed technology and produces pure water continuously without the use of regeneration chemicals. The stacks are designed for operation after double pass reverse osmosis. The stack has ability to produce ultrapure water with high flow rate using a patented “Split Flow EDI” technology. Applications include the semiconductor, power, food & beverage and pharmaceutical industry.

Advantages to FEDI HF:

| High flow per stack | Maximum product flow up to 7.1 m3/h (31 gpm) |

| Single voltage operation | Ease of operation with single voltage operation |

| CE Certified | FEDI HF stacks comply with 2014/35/EU directive on electrical safety |

| Ultra-pure water quality | Produces ultra-pure quality water of up to 16 MΩ.cm.

Meets water specifications for high pressure boilers and gas turbines, as well as a variety of other application |

FEDI GIGA

The FEDI-GIGA stack is a next-generation electrodeionization stack that is designed to produce ultrapure water with a high flow capacity. It can minimize associated piping and instruments due to its unique design feature – one inlet and two outlet ports. It is the first electro-deionization stack with three ports Feed, Product & Reject.

Advantages to FEDI GIGA:

| High flow per stack | Maximum product flow up to 15 m3/h (66 gpm) |

| Minimum Ports | Only three ports Feed, Product and Reject |

| Minimum piping and instrumentation | Reduced piping and instrumentation for the OEM |

| Single voltage operation | Ease of operation with single voltage operation |

| CE Certified | FEDI GIGA stacks comply with 2014/35/EU directive on electrical safety |

| Ultrapure water quality | Produces ultrapure quality water of up to 18 MΩ.cm |

| Low footprint | Compact design occupying low space and high throughput |

About FEDI Rx – Pharmaceutical Grade Water System

FEDI® Rx stacks are a pharmaceutical grade water system featuring hot water sanitization ability at 85°C. These stacks have the ability to produce high purity water quality up to 18 MΩcm using a patented process with double sets of electrodes per stack. FEDI Rx stacks are available in four sizes (5X, 10X, 20X & 30X). These stacks have widespread application in Pharmaceutical, Biomedical & Laboratories where hot water sanitization is required.

Value to FEDI Rx

Features/Benefits |

Value to Customer |

|

Hot Water Sanitization, 156 cycles |

Better Life Expectancy |

|

Delivers target product quality instantly |

Quick Startup |

|

Vertically integrated Manufacturing |

Certainty on Quality & Pricing |

|

FDA compliant/CE Certified |

FEDI Rx features and benefits FDA Compliant/CE certified- Pharma grade water quality |