Project Description

QUA Q-SEP® Ultrafiltration Technology Recycles Wastewater for Cooling Tower Make-Up Water in Leading Zinc-Lead-Silver Smelter Complex

Background

Background

Client: Leading Zinc-Lead-Silver Producer

Existing ETP Capacity: 792,516 GPD (3,000 m3/day)

Challenge –

- The ultrafiltration (UF) unit was integrated to enhance the

treatment efficiently of wastewater before it is supplied to the

reverse osmosis (RO) feed. - The aim was to produce water with a Silt Density Index (SDI) of less than 3, ensuring the treated water is compatible with the RO

membranes

The QUA solution was chosen because of its cost-effectiveness and ability to meet and exceed the treated water quality requirements for the RO feed water. The decision-making process included factors such as capital investments, space requirements, intended flux, and membrane surface area. Ultimately, the client selected the Q-SEP® 8012 model for its low-pressure operation and ease of integration following secondary treatment.

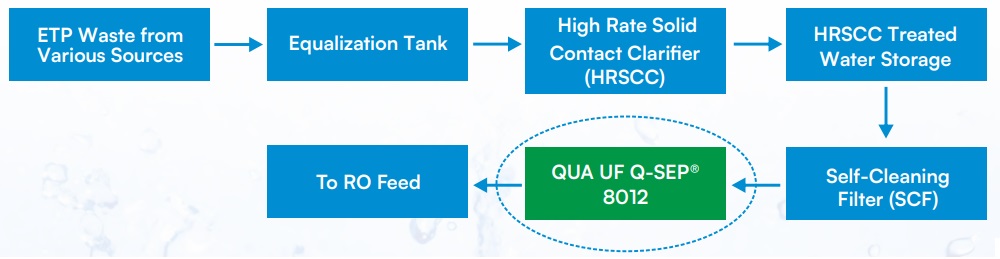

Plant Scheme –

Membrane system design offered:

|

QUA UF Model |

No. of Modules |

Nominal Pore Size(microns) |

Permeate Flow | Feed Water Turbidity (NTU) | Product Water Turbidity (NTU) |

| Q-SEP® Outside-In | 2 x 18 | 0.04 | 2 x 7 m3/hr | 30 |

0.1 |

Results

The UF system has been operational without issues since its implementation in September 2022. The product water is remarkably clear with turbidity values consistently between 0.1 to 0.2 NTU, and the SDI has remained below 3. The transmembrane pressure (TMP) has been kept below 0.5 kg/m3 contributing to reduced energy consumption. The system has also maintained a steady permeate flow rate of 71m /hr, which demonstrates reliable and efficient performance without compromising on total output. The RO permeate is further used for cooling tower make up water application and system further achieves zero liquid discharge through series of operations.