Project Description

Background

TCI Sanmar Chemicals S.A.E., located in Egypt, is one of the biggest producers of chemicals in the MENA (Middle East & North Africa) region. TCI has a state-of-the-art chemical manufacturing facility at Port Said, for manufacturing 200000 TPA of PVC (Polyvinyl Chloride) and 275000 TPA of caustic soda. These are the largest capacities in the MENA region. In Phase 2 of the project, the PVC capacity has been doubled and a new calcium chloride granule plant added.

Egypt being water scarce has local norms that demand minimum discharge of effluent from industrial plants. This requires provision of effluent recycle and reuse facilities for all industries in Egypt.

The Challenge

In the phase 2 expansion, out of the various wastewater streams to be treated, the PVC effluent posed a real challenge.

The effluent generated from the PVC manufacturing process carries large amounts of suspended solids consisting of very fine submicron size PVC particles that are difficult to separate and remove by conventional methods. These particles don’t easily settle by coagulation, flocculation and clarification processes, and easily get carried through the pre-treatment of Zero Liquid Discharge (ZLD), disturbing the performances of the ZLD mainstream units.

Once these submicron particles enter into the downstream units, particularly reverse osmosis membranes, they cannot be removed by chemical cleaning processes, thereby reducing the overall plant productivity.

Pilot Study

Considering the submicron size of the PVC particle and its unique characteristic, the OEM conducted a pilot on this effluent stream at the TCI Sanmar site using a combination of settling and floatation followed by ultrafiltration to achieve efficient separation of the particles from water. The pilot was performed using QUA’s Q-SEP Ultrafiltration Membranes.

The objective of the pilot plant study was to determine the performance of Dissolved Air floatation (DAF) and Ultrafiltration (UF) membranes on removal of PVC particles.

The pilot was successful and the results effectively demonstrated that the PVC non bio-degradable particles could be removed by the selected DAF-UF scheme at source, thus safeguarding the downstream RO unit. During the pilot, Q-SEP UF was able to provide consistent SDI in the range of 2-3 eliminating the fouling of RO membranes due to PVC particles generated from the manufacturing plant.

Final Scheme with Q-SEP UF

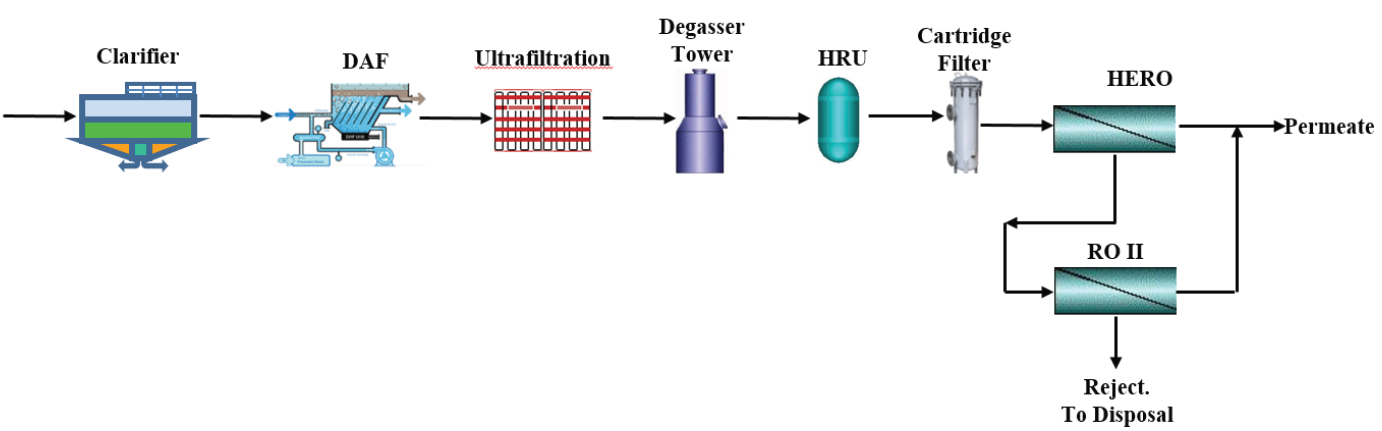

This being a specialized application for PVC recovery, and based on the successful pilot results, the final ETP scheme designed by OEM was configured with QUA’s Q-SEP UF.

UF removes the very fine submicron particles and the SDI of the water will be achieved prior to feeding to the downstream plant.

UF is the best pre-treatment technology for ensuring cost effective performance of the reverse osmosis system and is often used to remove suspended solids, colloids, and macromolecules from water. As pre-treatment for the RO system, UF significantly increases the life of RO membranes and reduces cleaning frequencies, thereby reducing operating expense for the RO system and improving the performance and productivity of the downstream RO units.

Model: Q-SEP 6008

Modules: 92 (2 streams x 46)

Flow: 2 x 133m3/hr

Application: ETP Recycle

QUA Solution

The UF system at TCI Sanmar Chemicals is comprised of two UF streams of 46 modules of Q-SEP 6008 each, a total of 92 modules. There are 2 parallel rows in each stream with 23 Q-SEP modules each.

The UF system is comprised of hollow fiber polyether sulfone (PES) Q-SEP® membranes as well as backwash and chemical dosing pumps. It is designed to operate in dead end mode thus increasing the overall recovery of the system. The system is fully automated ensuring minimal operator intervention.