Project Description

Background

The client, one of the oldest motorcycle manufacturers in continuous production, made its first motorcycle in the early 20th century in England. The company operates in India and over 50 countries around the world. With modern development facilities in the UK and Chennai, India, the client makes its motorcycles in Tamil Nadu.

Environmental regulations have made the treatment of effluent mandatory before allowing it to flow into the natural ecological system. The scarcity of fresh water availability has also necessitated that wastewater be treated for recycle and reuse.

The client has installed an Effluent Treatment Plant (ETP) to treat the wastewater generated from this unit. The ETP has complete pretreatment along with biological treatment. The tertiary treatment is comprised of Ultrafiltration (UF) followed by a Reverse Osmosis (RO) system. The RO permeate is recycled back to be used in the plant process.

The UF system in the RO pretreatment system is required to provide consistent product water with low silt density index (SDI).

QUA Solution

Q-SEP Model: Q-SEP 6008

Total Q-SEP Membranes: 10 (replacement) + 14 (repeat order)

Feed Flow: 22m3/hr + 30m3/hr

Feed Water: Automotive plant effluent treatment

The primary goal of RO pretreatment is to reduce SDI and turbidity of the water feeding the RO, to minimize cleaning and safeguard the RO membranes from fouling. The feed to the UF system is filtered water from media filter units, and the UF will remove any residual suspended solids, colloidal matter and high molecular weight organics in the feed water, to achieve low and consistent SDI required for reliable and trouble free RO operation.

The feed water to the UF plant in this ETP is tertiary treated effluent after the media filtration units. The unit operates at 22 m3/hr permeate flow.

Initially, the UF plant was configured with another manufacturer’s membranes. The UF system was comprised of 14 membranes, each with an area of 54m2. Though the plant had been running since early 2018, the UF membranes were not able to perform due to challenging feed parameters:

• The membranes were fouling and frequent chemical cleaning (CIP) was required for the UF and downstream RO systems.

• SDI was always above 5.

• The turbidity increased from 0.2 NTU to more than 1 NTU.

• The permeate flow came down from 22m3/hr to 12m3/hr, because of reduction in flux.

The existing UF system was thus unable to adequately pretreat the water and meet the client’s expected performance criteria, so they began exploring other UF membranes for replacement.

QUA Solution

The client and the OEM involved in this project approached QUA because of its experience, local support in terms of pre and post sales service and successfully running installations. QUA’s Q-SEP ultrafiltration membrane has been proven for its consistent and reliable operation because of its low fouling characteristics, uniform pore size distribution and large surface area. Q-SEP was thus able to provide a reliable solution and resolve the client’s concerns.

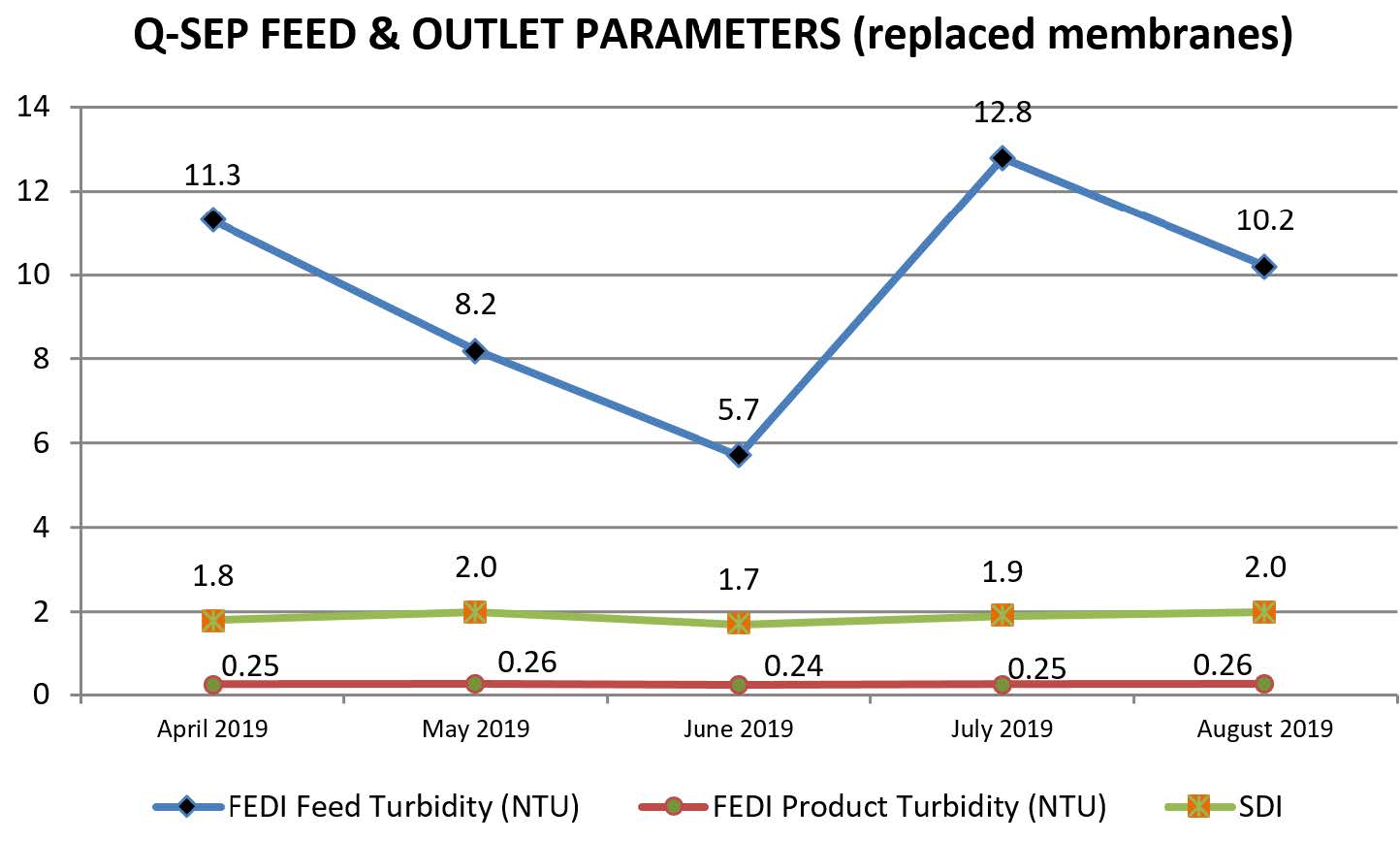

QUA supplied 10 units of Q-SEP 6008 for this plant. Q-SEP operates at a 33% higher flux of 40 LMH compared to the competitor’s membranes which operates at a flux of 29-30 LMH, so fewer units were required for replacement. Q-SEP thus enabled the client to save on the total system cost, due to the fewer number of membranes required. The replaced Q-SEP membranes have been operating since April 2019, and the client is very satisfied with the performance of the system:

• Q-SEP has continuously provided a consistent permeate output of 22m3/hr.

• The SDI at the outlet of Q-SEP is 2 or less, 100% of the time.

• Permeate turbidity has been <0.3 NTU.

• The Q-SEP pretreatment has resulted in lower RO cleaning frequency.

The Client has rewarded Q-SEP’s superior performance by placing a repeat order of 14 membranes for their phase II expansion project. These have been supplied and were commissioned in July 2019.

Q-SEP® Hollow Fiber Membranes

Q-SEP® hollow fiber ultrafiltration modules contain membranes manufactured with QUA’s innovative patented “Cloud Point Precipitation” method. This process ensures a high pore density along the length of the fiber and uniform narrow pore size distribution in the membrane. Q-SEP modules deliver superior performance characteristics and product water quality that surpass the quality from conventional UF modules. The narrow pore size distribution allows the membrane to produce water with a low silt density index (SDI). The lower product SDI leads to less frequent and easier cleaning of downstream RO membranes. In addition , the Q-SEP membranes provides an excellent rejection of bacteria and viruses.