Project Description

Integrating QUA’s FEDI® Solution for High-Purity Water in Green Hydrogen Production

Client: Leading Natural Gas Company an d Public Sector Undertaking (PSU) in India

d Public Sector Undertaking (PSU) in India

Capacity: 4.3 tones/day of Green Hydrogen (GH2) Production, with a purity of about 99.9% by volume

Challenges:

- The hydrogen Plant’s PEM Electrolyzer requires high purity water as feed water for GH2 production with a feed conductivity of 0.1 μS/cm.

- Ensuring consistent flow and conductivity for operational stability and performance while meeting stringent GH2 purity standards.

QUA Solution:

- After a detailed technical evaluation, the client selected QUA’s FEDI® Fractional Electrodeionization as the optimal solution for their specific requirements. FEDI® stacks are designed to produce high-purity water up to 18 MΩ.cm using a patented two stage separation process.

- Throughout the commissioning phase, QUA’s dedicated technical support team delivered exceptional pre- and post-sales assistance. A QUA representative was present on-site, ensuring seamless integration of the FEDI® system into the client’s operations.

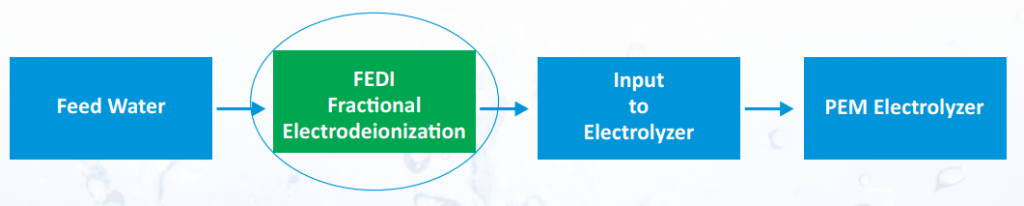

Flow Diagram:

Results

In the forthcoming period, PEM electrolyzers are likely to dominate green hydrogen production due to their ability to produce high-purity hydrogen gas (99.999%), essential for applications like fuel cell vehicles. High purity water is crucial for maintaining electrolyzer function, and inadequate water treatment can cause damage. The choice of electrolyzer technology and water source determines the required water treatment. FEDI® is an optimal solution for this application.

Since its commissioning in 2024, QUA’s FEDI® technology has reliably delivered type 2 purified water with a conductivity of 0.1 μS/cm, meeting the stringent purity requirements of green hydrogen production. QUA’s FEDI® supports sustainable hydrogen production and contributes to global efforts for a greener future.