Project Description

Background

The client is a renowned pharmaceutical company that is one of the world’s largest vaccine producers, and is based in Pune, India.

The client had a requirement for a sewage treatment plant for their new pharmaceutical manufacturing facility, and decided to use a membrane bioreactor (MBR) based solution over the conventional physical/chemical treatment, followed by media filters or ultrafiltration.

The client had space limitations, and MBR was preferred due to its capability of minimizing unit operations while still producing high quality, ultrafiltration-grade water for the client’s use. MBR systems take less space approximately one fourth of conventional activated sludge system.

The client had previously also chosen an MBR solution for a polluted river water treatment plant for use as influent for another facility, and the plant has been performing well since it was successfully commissioned in 2016.

QUA Solution

QUA had previously supplied EnviQ®, its submerged ultrafiltration MBR membranes, for the polluted river water treatment plant, and seeing the satisfactory performance, the client selected EnviQ again for their STP. MBR systems are robust and can handle organic fluctuations easily. As membranes are used as a physical barrier for solid liquid separation, MBR systems promise consistent high effluent quality in term of TSS and organic removal, and also require less chemical for disinfection.

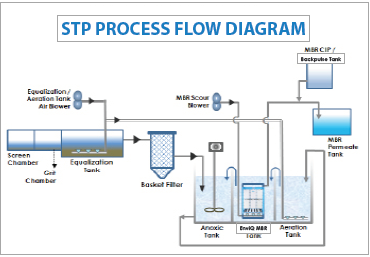

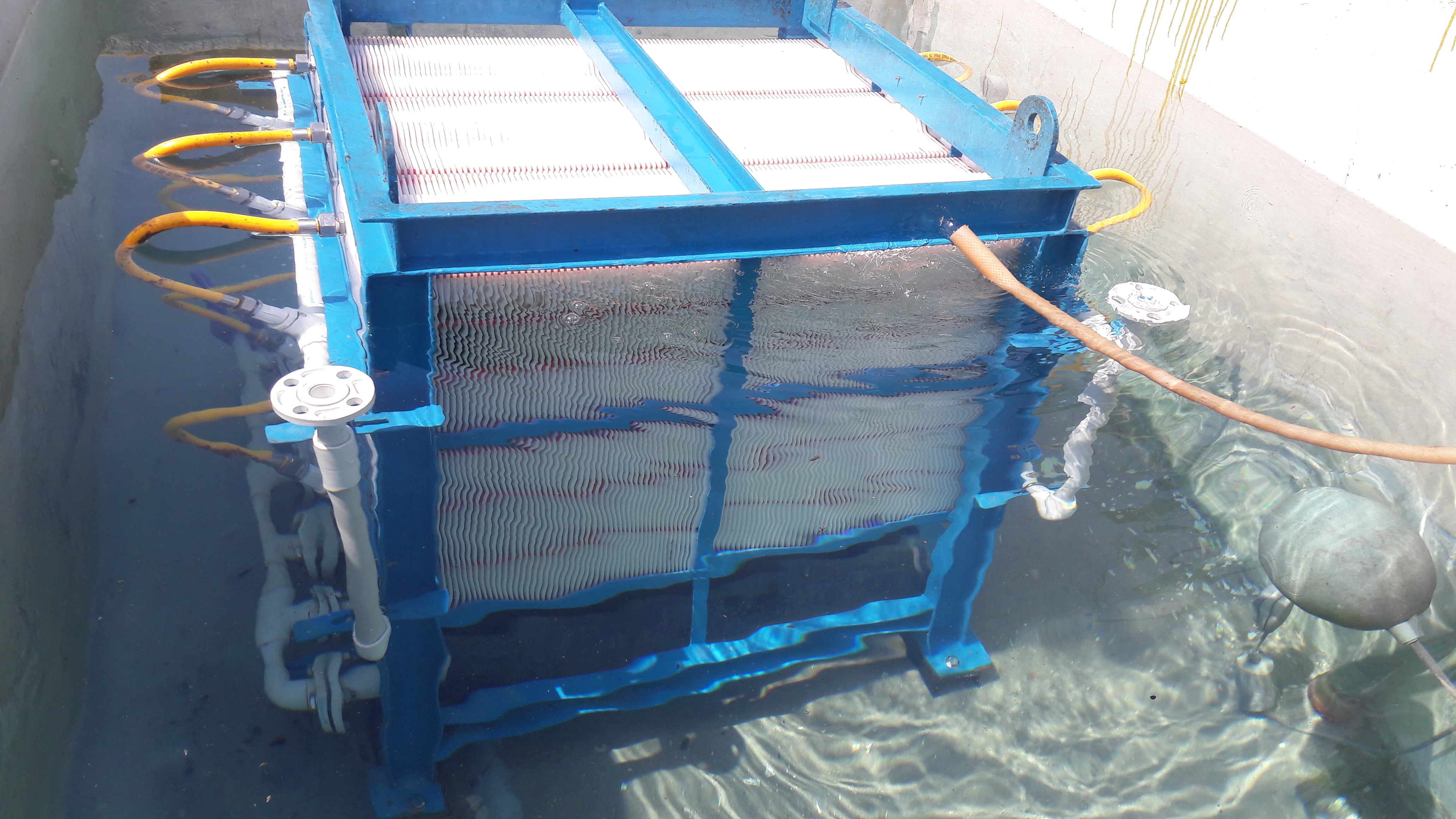

The QUA configuration consists of 3 EnviQ® 16C units in two streams, with a total of 6 units installed. The system is designed to treat 400 m3/day of the facilities sewage. The process is designed to receive MLSS of 5000 mg/l from the aeration tank, the design MLSS in the EnviQ MBR tank is 10000 mg/l.

EnviQ ultrafiltration membranes are submerged, flat sheet membranes with a pore size of 0.04μ. These membranes are less prone to clogging, easy to operate and do not require any forced back wash. Membrane chemical cleaning can be done in situ. EnviQ® is a unique patented technology that combines the ruggedness of flat sheet membranes with ultrafiltration quality water. Due to their lack of an external frame, the membrane cartridges are able to withstand harsh conditions while minimizing biofouling.

These advantages will serve to be very valuable to the client’s treatment plant to meet continued expectations.